Product

PVD Technology

2018-12-29 10:28

PVD is an abbreviation for Physical Vapor Deposition.

What is PVD technology?

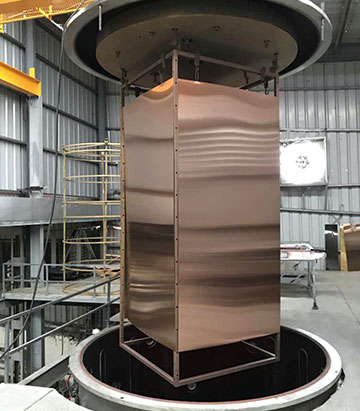

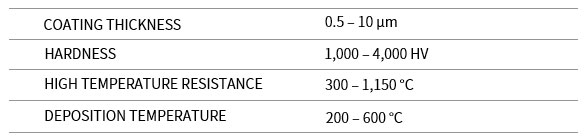

PVD is an abbreviation for Physical Vapor Deposition. PVD is a technique for vapor deposition of materials under vacuum. Vacuum chamber is an essential condition to avoid evaporating material and air. PVD coating is used to prepare new ones. The value and characteristics of the product, such as brilliant colors, wear resistance and friction reduction. The physical vapor deposition (PVD) process is used to form a coating by condensing most of the metal material and combining it with a gas, such as nitrogen. The matrix material is converted from a solid state to a gaseous state and is ionized by thermal energy as received in an arc process or ionized by kinetic energy as in a sputtering process. PVD technology is environmentally friendly and non-polluting. In general, Huicheng Vacuum focuses on PVD hard coatings (and PACVD coatings, see the next chapter).

Process Basics (PVD)

Coating structure:

• Multi-layer

• Nano composite coating

• Single layer

• Gradient coating

• Microalloyed layer

advantage:

• Excellent coating adhesion even at lower coating temperatures

• High output, suitable for mass production

• Flexibility in different component shapes, sizes, and quantities

• Strong anti-wear protection with low coefficient of friction

• Excellent hardness, oxidation resistance and reduced chemical reaction

typical application:

• Cutting Tools

• Primary tools for shaping, forming and forging

• Plastic processing tools

• Precision components

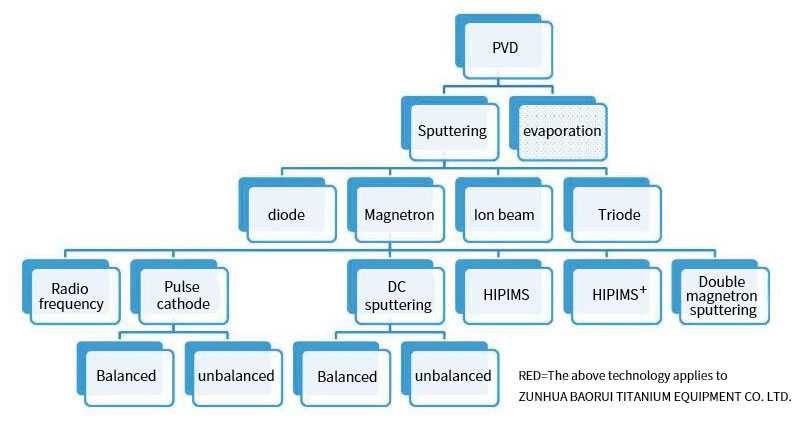

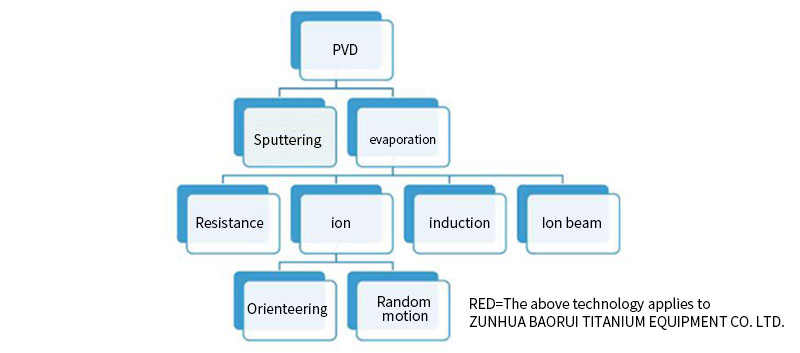

The contents of the small red box in the following chart are provided by the vacuum coating equipment produced by Huicheng:

- Prev: No

- Next: Vacuum Rquipment

Product

Top