Strip vacuum coating technology is an important research and development performance in modern times

With the traditional iron and steel industry to capital consumption, the environment load increases as the value to increase in the form of different, altered appearance function strip materials to develop new products, vacuum coating can be satisfied with function of environmental protection, reduce costs and save capital and progress of comprehensive request, and its potential is infinite in theory, because the appearance control degrees of freedom is big, can satisfied users of all kinds and sensitive changing needs. To develop new strip materials with appearance skills, the primary rely on skill innovation. Appearance skills will be the future of steel enterprises commodity innovation focus, is the location of enterprise competitiveness in the future. It is the best way to meet the market demand and improve the competitiveness of enterprises to develop a new generation of vacuum coating technology and products. The industrialisation of new physical skills and goods could revolutionise the production processes of steel mills and upstream and downstream occupations.

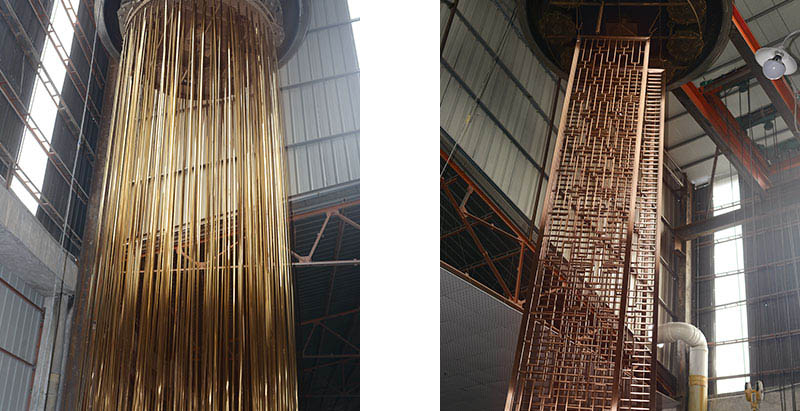

Market needs and existing skills limitations, difficult to through the optimization of traditional production line modification, more and more strict environmental protection norms also request for iron and steel enterprise the appearance of the new environmental protection process and plating skills, in this regard, the current steel industry professionals is generally believed that the most promising, the most characteristic of skills development direction is vacuum coating. Vacuum coating (including physical vapor deposition and chemical vapor deposition, etc.) is a variety of techniques to be plated into a gaseous material, forming a thin film coating on the surface of the strip. Theoretically, all metals, nonmetals and organic compounds can be deposited by this method. This skill can be combined to optimize multi-skill, highly sensitive composite coating skills to meet a variety of functional requirements. Therefore, the development and implementation of this new skill will be the best strategy for steel enterprises to deal with the appearance skills and commodities. It can be predicted that with the development of vacuum skills and data skills and the urgent request of the steel profession for the development of new steel products, the vacuum coating of strip steel will become a primary skill of strip surface treatment, which has an outstanding prospect. It provides a primary method for developing new strip data.

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

Compared with traditional electroless plating and hot dip plating, the primary characteristics of vacuum coating are:

(1) low film-forming temperature. Hot dip galvanized coating in steel professional temperature is 400 ℃ ~ 500 ℃, usually higher chemical deposition temperature above 1000 ℃. Such a high temperature is very simple to cause the deformation of the plating, transformation, and vacuum coating temperature is low, can be reduced to room temperature, to avoid the disadvantage of conventional coating skills.

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

(2) evaporation source has a large degree of freedom. The coating material that can choose is much and do not suffer data melting point to restrict, besides the zinc that is common in hot galvanizing, aluminium, tin, can evaporate the metallic data of plating all simply, the metallic nitriding film that still can plating a variety of a lot of kinds, metallic oxidation film and metallic carbonization content reach all sorts of compound film. This provides a great deal of freedom for developing new strip data.

(3) do not use harmful gas or liquid, and have no negative influence on the environment. This was extremely valuable in the general trend of paying more and more attention to environmental protection at that time.

(4) good coating quality. Uniform, smooth and extremely thin coating can be obtained with high purity, corrosion resistance and good adhesion. There is no hot galvanizing leakage plating point, zinc waves, zinc flowers and other questions.

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

(5) sensitive skills, easy to change the type. Can be plated single - sided, double - sided and single - layer, multi - layer and mixed layer. Film thickness is easy to control. After determining the coating time, can accurately control the coating thickness, and then avoid the hot dip galvanized in the common thickness is not easy to control and present zinc waves and other questions.

In short, the strip vacuum coating is a set of metallurgy, vacuum, chemistry, physics and other disciplines in one of the high and new skills, its products have high added value, both the strength of the strip and cheap features, but also after the coating of multi-functional, multi-species, high quality advantages, is a great potential for the development of new strip data direction.