Introduction to the application of vacuum coating and how to choose vacuum coating?

Vacuum coating machine use and operation method, vacuum coating machine is a common type of coating machine, mainly refers to a type of coating that needs to be carried out under high vacuum, including many varieties, including vacuum ion transpiration, magnetron sputtering , MBE molecular beam epitaxy, PLD laser sputtering stacking and many other types. The following small series is the first to introduce the vacuum coating machine use and commodity common sense, I hope to be able to assist us.

Vacuum coating machine use

The transpiration coating is usually a heating target to transpire the surface components in atomic or ionic manner. And it settles on the outer surface of the substrate, and a film is formed by a film formation process (scatter-island structure-vap structure-layer growth).

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

Regarding the sputtering type coating, it can be simply understood that the electrons or high-energy lasers are used to bombard the target material, and the surface components are sputtered by atomic group or ion, and finally piled up on the surface of the substrate, and the film forming process is experienced, and finally a film is formed.

Vacuum coating machine scope

1. Construction hardware: bathroom hardware (such as faucet). Door locks. Door handles. Bathroom, hardware hinges, furniture, etc.

2. Watchmaking industry: It can be used for the coating of the watch case and watch band, crystal products.

3. Other hardware: leather hardware rim stainless steel utensils, tool, die and the like .

4. Large workpieces: car wheels, stainless steel plates, signboards, sculptures, etc.

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

5, stainless steel tubes and plates (various appearances)

6, furniture, lamps, hotel appliances.

7, locks, handles, bathroom hardware, golf heads, stainless steel cutlery, blood and other hardware products plated super hard decoration film.

8, watches, straps, glasses, jewelry and other decoration products plated super wear-resistant decoration (gold and silver) nano-film and nano-film and nano-layered film.

The optional vacuum coating machine has the following points

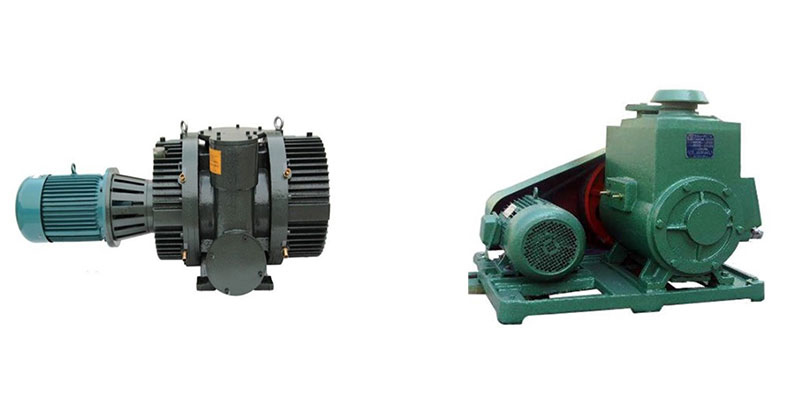

1. The vacuum system consists of mechanical pump, diffusion pump, augmentation pump, oil booster pump, Roots pump, 埚 wheel molecular pump, etc. and various pneumatic, manual, electric valves and pipelines matched with them.

2, according to the process requirements, choose different specifications and types of coating equipment, the types are resistance evaporation, electron beam evaporation, magnetron sputtering, magnetron reactive sputtering, ion plating, hollow cathode ion plating, multi-arc ion plating.

3. The furnace body can be selected from a double-layer water-cooled structure made of stainless steel, carbon steel or a combination thereof.

4. The working mode of the fixture has the functions of rotation, revolution and revolution + rotation. The user can make corresponding requirements according to the size and shape of the substrate, the speed range of rotation and the rotation accuracy: ordinary adjustable and variable frequency speed regulation.

5, the inflation method can choose mass flow meter, float flow meter + needle valve and corresponding inflation valve, and can choose multi-channel inflation pipeline and corresponding flow parameters.

Vacuum Coating Machine,Vacuum Plating Equipment,PVD Coating Equipment,PVD System,Gold Coating Machine

6. Select the plating method and form according to the process requirements. The vacuum measurement can select digital intelligent vacuum gauge and its high-quality measurement regulation, and other measuring instruments. The film thickness measurement can be selected from a sheet resistance measuring instrument, a transmittance meter, and the like.

7, according to the characteristics of the equipment, you can choose manual, semi-automatic, fully automatic or a combination of control methods.

8. According to the structure to be baked, the baking temperature, material and the corresponding instrument measurement are required.

9. Perfect alarm system, sound and light alarm for abnormal conditions such as vacuum chamber body, water shortage, diffusion pump phase failure, air pressure, over-voltage of power supply load and over-current.